In 2011, 20% of companies in the S&P500 published a sustainability report; by 2019 this rose to 90%. In 2021, companies releasing transparent reports on their environmental impacts are now the norm.

Assessing environmental impacts using a methodology called Life Cycle Assessment (LCA) has been a huge leap forward for companies in measuring, managing, and reporting the overall impact they are having on the environment.

As companies seek to understand more about the impact they are having on the environment – and how they can reduce it further – they need ever more precise ways of assessing their environmental impacts. To get this level of precision, more and more companies are turning to LCA studies of individual products.

Product-level LCA studies are an individualized assessment of how the life cycle of a specific product affects the environment across a wide range of categories, from climate change to ozone depletion and more.

The most ambitious companies are looking to perform an LCA study for every product in their portfolio.

Product-specific LCA studies are a response to four major sources of pressure to increase disclosure on environmental impact:

- Conscious consumerism– Consumers want to know the environmental impact of the products they purchase

- Risk-averse investment– Investors demand to know that a business is not built on products that pose a high risk to the environment

“Companies have a responsibility – and an economic imperative – to give shareholders a clear picture of their preparedness.” – Larry Fink, CEO of the world’s largest asset manager, Blackrock.

- Regulation – As more and more countries set legally binding climate targets, regulatory pressure for companies to manage their carbon footprints is increasing

- Internal decision-making – Decision-makers need clarity on how to respond to the three pressures above, even down to a product-by-product level

The automotive industry is facing new challenges relating to the four pressures above. The focus of the industry’s discussion now goes far beyond direct emission values to include the overall life-cycle environmental impacts of automotive products. A holistic assessment of these product environmental impacts must cover all the major components of the product, including those that come from the upstream supply chain, such as synthetic materials. To satisfy the rise in demand for LCA studies of automotive products, suppliers in the automotive supply chain are under increasing pressure to provide environmental data on each product they provide.

As useful as product LCA studies are, for them to be practical in the industry they must be both as accurate as possible and easy to produce on a large scale.

These two challenges have long been hard to overcome, mostly because of problems related to the data product life cycle assessments rely on.

Data that truly represents a product’s entire life cycle, including notoriously opaque supply chains (so-called ‘Scope 3 emissions), has been almost impossible to find. Furthermore, integrating data from the many different stages in a product’s life cycle, including (again) the stages in the upstream supply chain, has also been incredibly difficult.

In short, manually assessing each product’s life cycle impacts on an entire product portfolio is so time-consuming and difficult that it’s often not practical.

However, automated LCA tools that combine representative data and automatic data gathering for entire product portfolios are starting to become available.

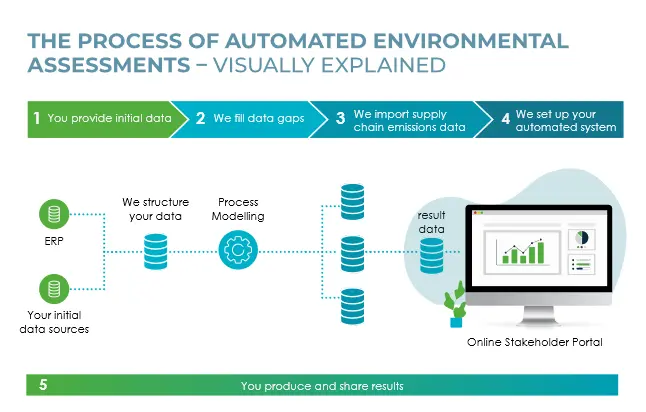

MHP “Our Partner” and Carbon Minds have been working together with the GFaI to design a comprehensive tool for automated, portfolio-scale product life cycle assessment. The tool works in a five-stage process like this:

IMPORT EXISTING DATA

A company imports data it already has in different formats, geographical locations, and systems (like Enterprise Resource Planning systems). From that data, the tool creates a new, consistent database.

CLOSING DATA GAPS

Most companies track economically relevant data, but not environmental data. The tool fills this environmental data gap with highly specific estimates. These estimates only require existing process data – automated modeling then estimates direct emissions along with other emissions, such as emissions from waste incineration.

IMPORTING SUPPLY CHAIN DATA

For manufactured goods, up to 90% of a product’s environmental impact comes from the supply chain. To account for these impacts, the tool imports data from specialized life-cycle inventory databases like Carbon Minds’ cm. chemicals and others.

AUTOMATING THE TOOL

To run the tool, we install a secure software system and then initialize it with the dataset described above. To keep the data coming in automatically, we connect the system to the company’s internal data sources. This completes the automated environmental assessment system.

PRODUCING AND SHARING PRODUCT CARBON FOOTPRINTS

The company can then use the tool to produce the product life cycle assessment it needs. To share the results, the tool can produce intuitive visuals. These visuals are uploaded seamlessly to an online platform where internal and external stakeholders can view the product LCA results.

With an automated product life cycle assessment tool like this, representative data are combined to create accurate product-specific LCA studies across entire product portfolios.

These are the tools that will empower internal decision-makers to respond to the pressures of consumers, investors, and regulators over these crunch years of the climate crisis.

*All rights reserved to MHP