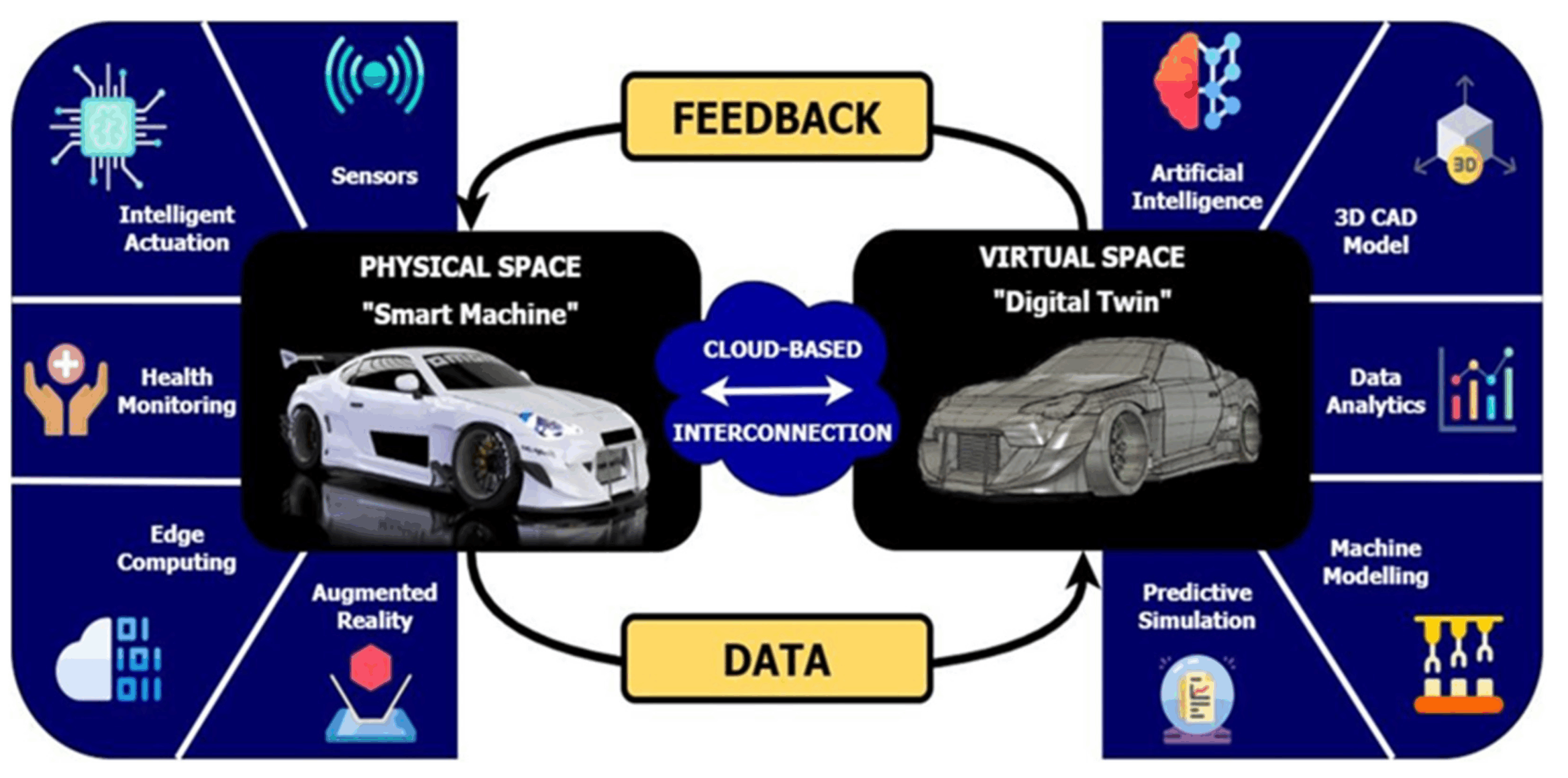

The automotive industry has undergone a profound transformation, blending its traditional infrastructure with cutting-edge technologies. One of the most groundbreaking innovations in this evolution is the use of Digital Twins in Automotive. A Digital Twin is a real-time, data-driven replica of a physical object or system, which helps automotive manufacturers improve the vehicle lifecycle and design future-ready cars. Digital Twins in Automotive are now central to vehicle R&D, OTA (Over-the-Air) testing, and smart vehicle maintenance.

Revolutionizing R&D with Digital Twins in Automotive

Before a vehicle reaches the market, it must pass through rigorous stages of design and control. Initially, engineers develop models using CAD tools, followed by physical prototyping, now enhanced with 3D printing. However, this process becomes increasingly complex due to the growing number of in-vehicle systems.

By simulating real-time behavior, Digital Twins in Automotive provide invaluable insights during early-stage development. They test system interoperability and performance, reducing the need for time-consuming physical testing. AI integration enables the prediction of failure rates and informs design decisions, ultimately saving costs and ensuring optimal component compatibility.

OTA Testing and Lifecycle Optimization with Digital Twins in Automotive

Digital Twins in Automotive continue to deliver value after market launch. In OTA testing scenarios, they simulate new software or hardware updates under various conditions before public release. This process optimizes performance and reduces risk.

Moreover, real-time component tracking through Digital Twins allows manufacturers to detect and isolate faults—such as corroded parts in transport—without massive recalls. Performance predictions and configuration tweaks can also be executed remotely, maximizing uptime and customer satisfaction.

Supporting Electric Vehicles (EVs) with Digital Twins in Automotive

Electric vehicles particularly benefit from Digital Twin technology. With sensors collecting real-time feedback, manufacturers can detect potential failures early. Tesla, for example, integrates a Digital Twin in each vehicle to monitor its mechanical systems and deploy OTA updates to fix issues instantly, without service center visits.

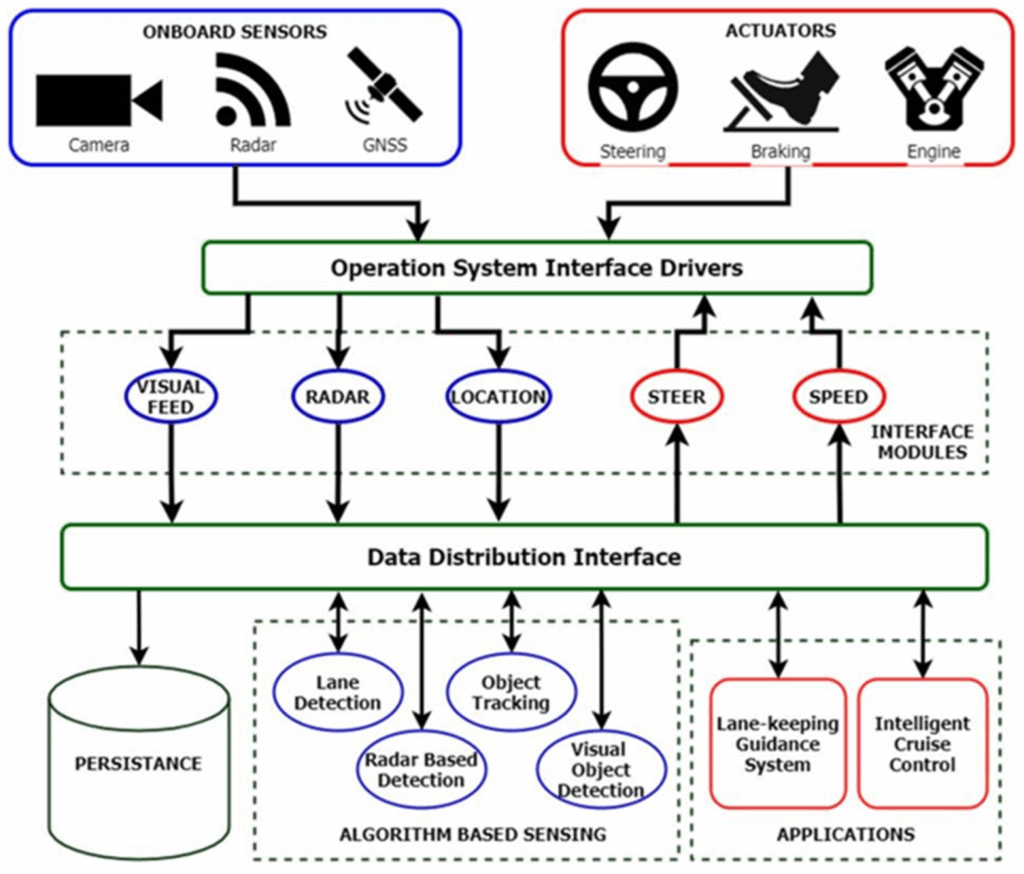

Enhancing Safety through ADAS and Fuzzy Logic with Digital Twins in Automotive

Advanced Driver Assistance Systems (ADAS) rely heavily on Digital Twins. These systems use cloud-stored sensor data to anticipate threats and prevent accidents. By integrating fuzzy logic and cloud intelligence, Digital Twins help evolve ADAS into autonomous driving support systems. They ensure compliance with safety regulations while respecting data privacy, aiding public trust and adoption.

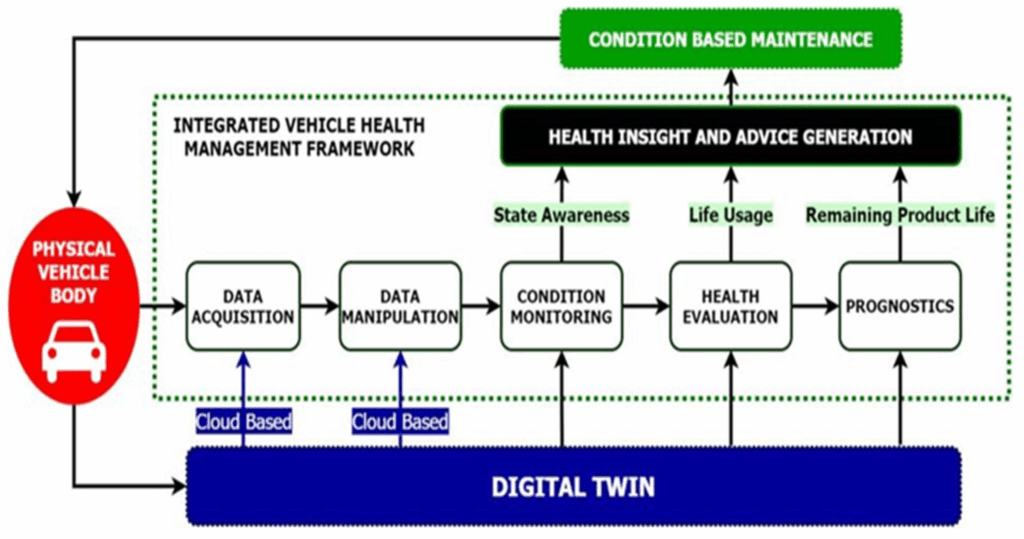

Maintenance, Repair, and Health Monitoring

Digital Twins play a pivotal role in Maintenance, Repair, and Operations (MRO). They simulate electronic systems, detect electromagnetic anomalies, assess brake wear, and analyze vehicle dynamics. This predictive maintenance ensures that even components like electric motors—subject to inevitable degradation—are monitored accurately, improving vehicle longevity and performance.

Conclusion

Digital Twin technology is reshaping the automotive industry by bridging the gap between virtual simulation and real-world performance. From R&D and OTA updates to personalized user experience and predictive maintenance, its impact is widespread. As AI and IoT technologies evolve, Digital Twins will become indispensable in building safer, smarter, and more efficient vehicles. Horizon Connect is here to support this transformation by providing customized automotive connectivity solutions, enabling real-time data integration, secure OTA update testing, and intelligent vehicle communication systems.

References

This article was inspired by “Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence by Dimitrios Piromalis and Antreas Kantaros.”